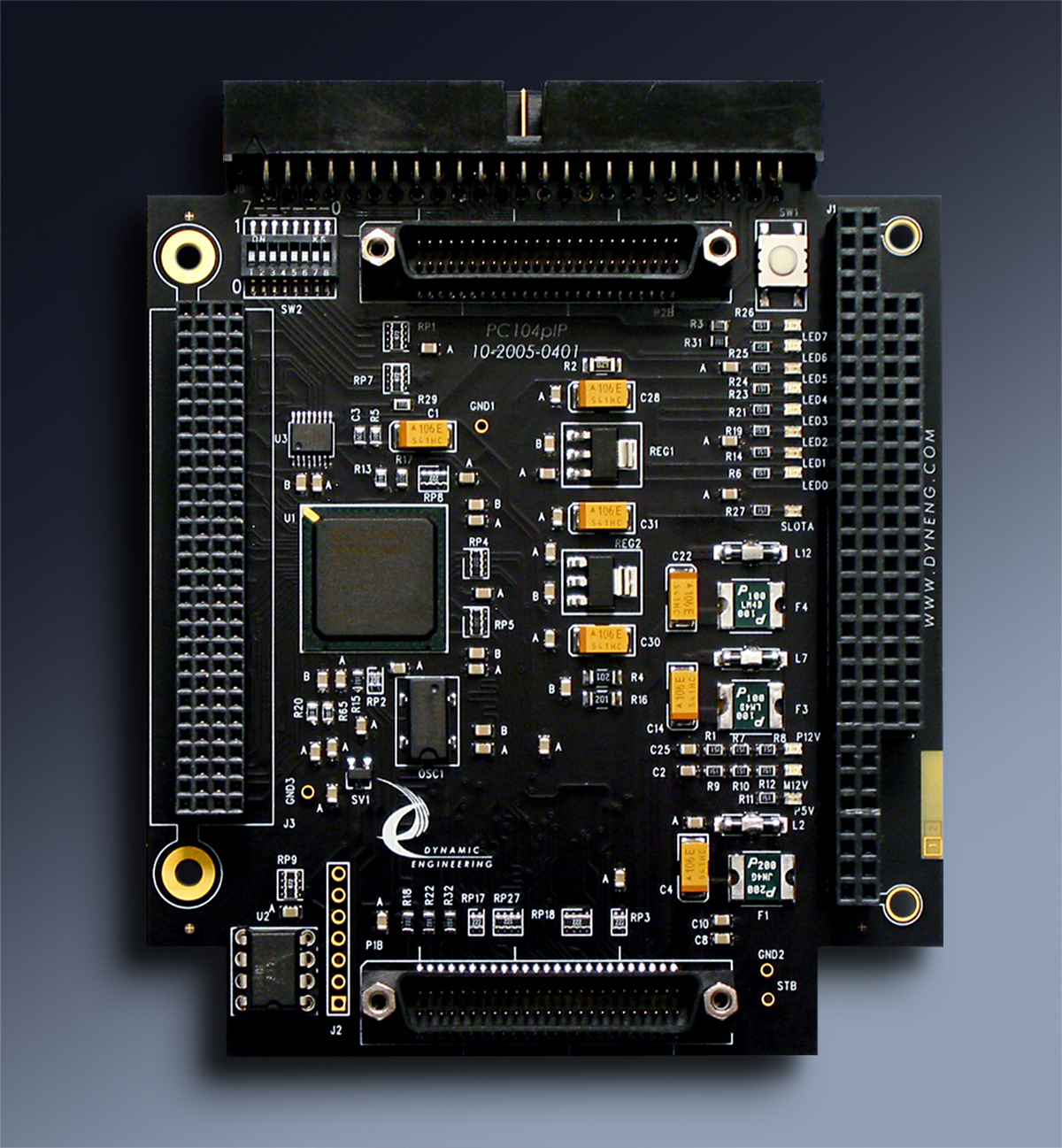

PC104pIP

PCI-104 adapter for IP Module.

Order This Item

PC104pIP Description

- Windows® , Linux driver included with purchase

- IndustryPack Module position w/ 8⇆32 MHz. operation

- Independent IP control buses with overlapped instruction execution

- Fused, FIltered 5V, +12V, -12V supplied to IP

- Multi-word accesses supported including 32, 16, 8 bit to IP´s

- Full memory space supplied to each position

- Standard PCI-104 or PC104p

- Ribbon Cable Header

- 1 year warranty standard. Extended warranty available.

- Extended [Industrial] Temperature standard.

- ROHS and Standard processing available

IndustryPack® Modules are an important part of solutions for Embedded situations. Rugged, small, light ... just right for many applications. IndustryPack® Modules require a carrier to adapt them to the system. Dynamic Engineering has carrier solutions for a variety of formats.

If you want to use IndustryPack® modules with your PC104p or PCI-104 system PC104pIP is the choice for you. PC104pIP combines features you need with simplicity and speed. One IP module can be installed per carrier. Multiple carriers can be used in a stack. PC104pIP is highly integrated with the PCI and IP interfaces closely coupled within the same FPGA. As a result PC104pIP is faster, has a higher MTBF, and is easy to use. There are fewer initialization steps, and more features. With the Windows® driver; operation can be "plug and play". Linux driver also available. PC104p Chassis(s) is available PC104p chassis to house your project.

PC104pIP is part of the IP Compatible family of modular I/O components. PC104pIP provides one IndustryPack® module site per PCI-104 stack position. PC104pIP acts as an adapter, converter, carrier, and bridge between the PCI bus and your IndustryPack® hardware.

PC104pIP is supported with Windows® compliant drivers for Win7 / 10 etc. as well as Linux and VxWorks support. The drivers come with a generic IP driver to allow use with "unknown" IP´s <=> IP´s that do not have a driver designed yet. For example, third party IP´s.

The PC/104p basic card size is smaller than the length of an IP module. The PC/104p specification allows for an added connector area of .5" on two edges. The "lower" connector area is used for the IP Module extension. The "upper" is used for the cable edge connector. The IP Module [type 1] when mounted is slightly smaller in height than the allowable component height for the PC104pIP plus the rear height of the board in the stack above the PC104pIP. If Type II or Type III modules are to be mounted or if the other cards in the stack have components in the rear mounting area then the PC104pIP will need to be mounted at the top of the stack or connector extenders used to create additional headroom.

Multi-board operation is supported. With multiple PC104pIPs in your system and unique cabling, sensors etc. for each stack position it is important to "know" which PC104pIP is which, and to properly control the IP modules mounted to them. A surface mount "dip switch" is provided to provide an identifier to the software. A specific PC104pIP can be matched with the PCI address allocated to make for deterministic control. The switch can be used for other purposes; configuration control or debugging for example. The switch values are available to be read via the PCI bus.

The IP position has a separate clock controller for 8 and 32 MHz operation. Glitch free operation means the frequency can be be changed on the fly. Series and parallel terminations with equal length traces insure clean clocks and coherant operation between the IP and the controlling state-machine. A well designed clock distribution is critical for reliable operation.

Resettable "self healing" fused filtered power. +5, +12, and -12V supported.

An Industry standard 50 pin [ribbon cable] headers is used with the IP IO connector. Ribbon cable or discrete wire cables can be interfaced directly with the PC104pIP. Alternatively the HDRterm50 can be used to create a terminal block interface.

Three methods of resetting the IP are built into the PC104pIP. The IP can be reset from the control register within the FPGA via the software interface. The IP is reset on power-up via a supervisory circuit that guarantees the 200 mS minimum reset requirement in the IP specification. The resets only affect the IP.

An LED is provided to show IP slot activity. When accessed the LED is flashed. The Xilinx provides a "one shot" circuit to stretch the "on" time to make it visible. Power indicator LED´s [3] are provided. An additional eight user LED´s are available for debugging or other purposes.

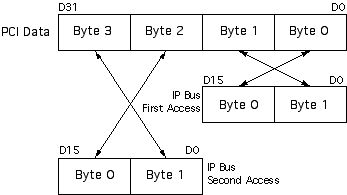

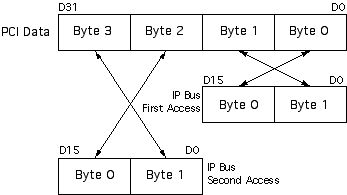

IndustryPacks are usually 16 bit devices and the PCI bus supports 32 bits. PC104pIP accepts 32 bit PCI accesses and converts them into two 16 bit accesses with an auto-incremented or static address. One PCI access can be used to write to, or read from two IP locations or twice to one location. Byte, Word and Long Word accesses are supported to the 16 and 32 bit IP sites from the PCI bus.

The IP accesses are protected by a watch-dog timer. The timer is started at the beginning of each IP access. If the timer expires before the IP being accessed responds, a bus error internal to the PC104pIP is created. The PC104pIP responds normally to the host, not tying up the PCI bus, and provides status and an optional interrupt to alert the host to the problem with the IP. The Bus Error timer is useful in situations where the software may want to cause a bus error to find out what is installed or where a hung system would have consequences. Multi-threaded software operation is supported with separate bus error status in each of the slot control registers.

The PCI bus is defined as little endian and many IP´s have their register sets defined to operate efficiently with a little endian interface. The default settings on the PC104pIP are "straight through" byte for byte and D15-0 written to address 0x00 before D31-D16 written to address 0x02 when long words are written to 16 bit ports. Please note that any long word address can be used. The lower data is written to the lower address first, then the upper data to the upper address. The IP slot has a ByteSwap and WordSwap control bit to allow Byte and Word Swapping to be performed to accommodate alternate IP and OS requirements.

Byte Swapping accesses to a 16 bit port.

Connector positioning is compatible with IP-Debug-Bus to allow the user to isolate and debug the control interface of an IP. The IP-Debug-IO can be used in conjunction with the PC104pIP and IP-Debug-Bus to provide test-points on the IO signals and loop-back capability for the IP.

PC104pIP is an extended temperature board. This extended or "Industrial Temp" design has components rated for -40C to +85C minimum. This temperature range will need to be derated based on your chassis thermal situation.

If you want to use IndustryPack® modules with your PC104p or PCI-104 system PC104pIP is the choice for you. PC104pIP combines features you need with simplicity and speed. One IP module can be installed per carrier. Multiple carriers can be used in a stack. PC104pIP is highly integrated with the PCI and IP interfaces closely coupled within the same FPGA. As a result PC104pIP is faster, has a higher MTBF, and is easy to use. There are fewer initialization steps, and more features. With the Windows® driver; operation can be "plug and play". Linux driver also available. PC104p Chassis(s) is available PC104p chassis to house your project.

PC104pIP is part of the IP Compatible family of modular I/O components. PC104pIP provides one IndustryPack® module site per PCI-104 stack position. PC104pIP acts as an adapter, converter, carrier, and bridge between the PCI bus and your IndustryPack® hardware.

PC104pIP is supported with Windows® compliant drivers for Win7 / 10 etc. as well as Linux and VxWorks support. The drivers come with a generic IP driver to allow use with "unknown" IP´s <=> IP´s that do not have a driver designed yet. For example, third party IP´s.

The PC/104p basic card size is smaller than the length of an IP module. The PC/104p specification allows for an added connector area of .5" on two edges. The "lower" connector area is used for the IP Module extension. The "upper" is used for the cable edge connector. The IP Module [type 1] when mounted is slightly smaller in height than the allowable component height for the PC104pIP plus the rear height of the board in the stack above the PC104pIP. If Type II or Type III modules are to be mounted or if the other cards in the stack have components in the rear mounting area then the PC104pIP will need to be mounted at the top of the stack or connector extenders used to create additional headroom.

Multi-board operation is supported. With multiple PC104pIPs in your system and unique cabling, sensors etc. for each stack position it is important to "know" which PC104pIP is which, and to properly control the IP modules mounted to them. A surface mount "dip switch" is provided to provide an identifier to the software. A specific PC104pIP can be matched with the PCI address allocated to make for deterministic control. The switch can be used for other purposes; configuration control or debugging for example. The switch values are available to be read via the PCI bus.

The IP position has a separate clock controller for 8 and 32 MHz operation. Glitch free operation means the frequency can be be changed on the fly. Series and parallel terminations with equal length traces insure clean clocks and coherant operation between the IP and the controlling state-machine. A well designed clock distribution is critical for reliable operation.

Resettable "self healing" fused filtered power. +5, +12, and -12V supported.

An Industry standard 50 pin [ribbon cable] headers is used with the IP IO connector. Ribbon cable or discrete wire cables can be interfaced directly with the PC104pIP. Alternatively the HDRterm50 can be used to create a terminal block interface.

Three methods of resetting the IP are built into the PC104pIP. The IP can be reset from the control register within the FPGA via the software interface. The IP is reset on power-up via a supervisory circuit that guarantees the 200 mS minimum reset requirement in the IP specification. The resets only affect the IP.

An LED is provided to show IP slot activity. When accessed the LED is flashed. The Xilinx provides a "one shot" circuit to stretch the "on" time to make it visible. Power indicator LED´s [3] are provided. An additional eight user LED´s are available for debugging or other purposes.

IndustryPacks are usually 16 bit devices and the PCI bus supports 32 bits. PC104pIP accepts 32 bit PCI accesses and converts them into two 16 bit accesses with an auto-incremented or static address. One PCI access can be used to write to, or read from two IP locations or twice to one location. Byte, Word and Long Word accesses are supported to the 16 and 32 bit IP sites from the PCI bus.

The IP accesses are protected by a watch-dog timer. The timer is started at the beginning of each IP access. If the timer expires before the IP being accessed responds, a bus error internal to the PC104pIP is created. The PC104pIP responds normally to the host, not tying up the PCI bus, and provides status and an optional interrupt to alert the host to the problem with the IP. The Bus Error timer is useful in situations where the software may want to cause a bus error to find out what is installed or where a hung system would have consequences. Multi-threaded software operation is supported with separate bus error status in each of the slot control registers.

The PCI bus is defined as little endian and many IP´s have their register sets defined to operate efficiently with a little endian interface. The default settings on the PC104pIP are "straight through" byte for byte and D15-0 written to address 0x00 before D31-D16 written to address 0x02 when long words are written to 16 bit ports. Please note that any long word address can be used. The lower data is written to the lower address first, then the upper data to the upper address. The IP slot has a ByteSwap and WordSwap control bit to allow Byte and Word Swapping to be performed to accommodate alternate IP and OS requirements.

Byte Swapping accesses to a 16 bit port.

Connector positioning is compatible with IP-Debug-Bus to allow the user to isolate and debug the control interface of an IP. The IP-Debug-IO can be used in conjunction with the PC104pIP and IP-Debug-Bus to provide test-points on the IO signals and loop-back capability for the IP.

PC104pIP is an extended temperature board. This extended or "Industrial Temp" design has components rated for -40C to +85C minimum. This temperature range will need to be derated based on your chassis thermal situation.

PC104pIP Features

Size

PCI-104 or PC104p card.

IP compatible slots

1 position.

Clocks

8 and 32 MHz operation. Clock selection can be changed on-the-fly with glitch free operation.

Access Width

IP Module slot can be accessed as byte, word, or long word. Long words are converted to double word accesses

Bus Error

The Watch-Dog timer protects against PCIe bus hangs by responding when the IP is not installed or has a failure.

Cable interface

Industry standard 50 pin box header connector

Software Interface

Control registers are read-writeable. IO, ID, MEM, INT spaces supported. Windows® , Linux Drivers available

Interrupts

The IP has 2 potential interrupts. Both are routed to INTA on the PCI bus. Control registers are provided to determine the source of the interrupt

Power Requirement

+5V, +12V, -12V current determined by IP installed. 5V is used to make 3.3V and 2.5V used by FPGA.

DIP switch

An 8 position switch is available to allow for configuration control, or to facilitate debugging, and to provide a positive ID of each PCIe3IP in your system

LEDs

+5V, +12V, -12V and activity LED. 8 user LEDs also provided

Reliability

estimated 1.37 million hours. Bellcore. GB 25c

PC104pIP Benefits

Speed

With the direct PCI to IP Bridge design featured in PC104pIP the access to your hardware happens faster than in competing designs. The 32 bit access capabilities and overlapped IP access further extends the lead in speed. Compatible with mult-processor systems without sacrificing access times for single CPU systems.

Price

System level cost is best when reasonably priced reliable hardware is used and NRE minimized. With PC104pIP, driver support for the carrier and IP level, reference software, history of reliable operation, and fantastic client support your cost per unit and overall costs are attractive. Please check the current per item pricing with the storefront lower on this page. Orders can be placed via the on-line ordering system or via phone / email PO order systems.

Ease of Use

PC104pIP is easy to use. A point and shoot user interface to the IP sites. Please download the manuals and see for yourself. Reference software is provided in source form to get you started. The generic IP interface allows the driver to be used with IP´s without a driver specific to that design.

Availability

We work to keep PC104pIP in stock. With our on-site manufacturing capability larger orders and out-of-stock situations are resolved quickly.

IP Specification Compatibility

PC104pIP is IP compliant per the VITA 4 - 1995 specification. All Dynamic Engineering IP Modules are compatible with the PC104pIP. All other IP Modules which are compliant with the VITA specification can be expected to work. ID, IO, INT, and Memory spaces are supported.

PCI Compatibility

PC104pIP is universal voltage, PCI compliant device. PC104pIP can be expected to work in any PCI / PC/104p / PCI-104 compliant system.

Part Number: PC104pIP

Ordering Options

- PC104pIP Standard board - Configured with both connectors for PC104p stack. PCI side used for communication with IP. 8 and 32 MHz IP operation, automatic 32 bit conversion, 50 pin box header for IO.

- PCI-104IP same as PC104pIP except stacking connector [ISA side] is not installed. Add -options as desired

- -ROHS Use ROHS processing. Standard processing is ""leaded"

- -CC Option to add Conformal Coating

PC104pIP Drivers

Software Support for PCIe3IP includes: Windows®, Linux compliant drivers

Please see the Driver manuals for the specifics of each type.

PC104pIP Windows® or Linux drivers for PC104pIP. The drivers are designed to be overlayed with individual IP Module(s) driver(s). IP drivers are auto installed for each instance detected. Please see the Driver manual for the specifics of writing your board interface. Please contact Dynamic Engineering if you would like us to produce one for your IP or a third party design. Our Windows and Linux drivers come with IP-Generic which is automatically installed when a specific driver is not found for a particular IP Module. IP-Generic can be used to control your IP including handling interrupts, and accesses to all 4 space types.

Linux

The PC104pIP Linux driver is a bus driver capable of supporting multiple (up to 64) Industry Pack buses/carrier cards. This driver interfaces with the ipack-core Open Source code to support Industry Pack devices. This Open Source code has been slightly modified, and is included with the tar-ball for this driver.

A generic IPACK driver (ipack_gen) and user library (libipack) has been developed by Dynamic Engineering. This driver and library may be sufficient for developing user space drivers for a device depending upon the complexity of that device. Other device specific user libraries and kernel drivers are available for Dynamic Engineering Industry Pack modules. The diagram below illustrates possible layering of Industry Pack components:

Integration support is available. Please contact Dynamic Engineering for this option or download the Technical Support Description from the Company button.

Please see the Driver manuals for the specifics of each type.

PC104pIP Windows® or Linux drivers for PC104pIP. The drivers are designed to be overlayed with individual IP Module(s) driver(s). IP drivers are auto installed for each instance detected. Please see the Driver manual for the specifics of writing your board interface. Please contact Dynamic Engineering if you would like us to produce one for your IP or a third party design. Our Windows and Linux drivers come with IP-Generic which is automatically installed when a specific driver is not found for a particular IP Module. IP-Generic can be used to control your IP including handling interrupts, and accesses to all 4 space types.

Linux

The PC104pIP Linux driver is a bus driver capable of supporting multiple (up to 64) Industry Pack buses/carrier cards. This driver interfaces with the ipack-core Open Source code to support Industry Pack devices. This Open Source code has been slightly modified, and is included with the tar-ball for this driver.

A generic IPACK driver (ipack_gen) and user library (libipack) has been developed by Dynamic Engineering. This driver and library may be sufficient for developing user space drivers for a device depending upon the complexity of that device. Other device specific user libraries and kernel drivers are available for Dynamic Engineering Industry Pack modules. The diagram below illustrates possible layering of Industry Pack components:

Integration support is available. Please contact Dynamic Engineering for this option or download the Technical Support Description from the Company button.

PC104pIP Manuals

Click on the link to Download selected manuals in PDF format.

Download the PC104pIP Hardware Manual in PDF format.

Download the IP Carrier Windows®10 manual. For PCIe and PCI based carriers

Download the Win10 Generic IP Driver Manual in PDF format.

Download the IP Carrier Windows®7 manual. For PCIe and PCI based carriers

Download the IP Carrier and Module Quick Start guide for Windows®7

Download the Win7 Generic IP Driver Manual in PDF format.

Download the IP Carrier Linux Manual

Download the Linux IP Module Manual

Download the PC104pIP Statement of Volatility

Download the PC104pIP Hardware Manual in PDF format.

Download the IP Carrier Windows®10 manual. For PCIe and PCI based carriers

Download the Win10 Generic IP Driver Manual in PDF format.

Download the IP Carrier Windows®7 manual. For PCIe and PCI based carriers

Download the IP Carrier and Module Quick Start guide for Windows®7

Download the Win7 Generic IP Driver Manual in PDF format.

Download the IP Carrier Linux Manual

Download the Linux IP Module Manual

Download the PC104pIP Statement of Volatility