IP-Debug-Bus

Order This Item

IP-Debug-Bus Description

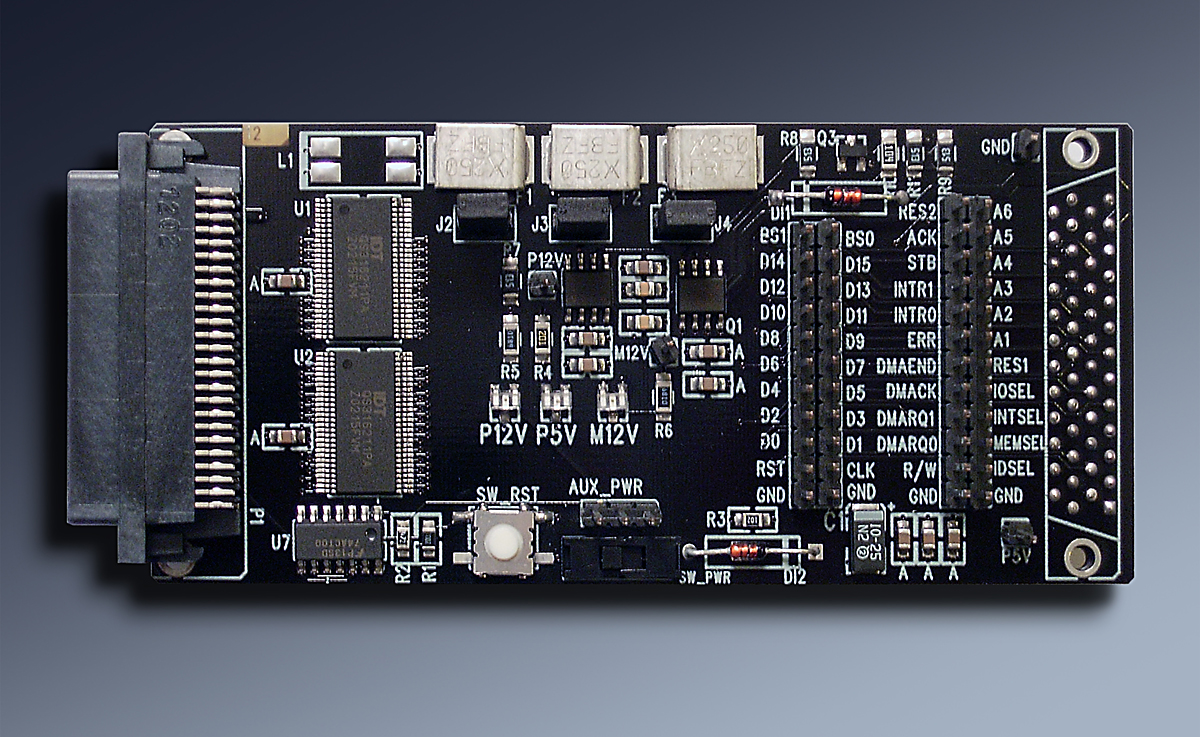

IP-Debug-Bus is a specialized extender card optimized for Integration, and test of IP Modules. The IndustryPack control bus signals are accessible via test points. The testpoints include multiple ground locations and .025 sq. posts for ease of connection to your logic analyzer or scope. The testpoints are labeled in the silkscreen for easy identification.

All IP Module control bus signals covered including rarely used ones like "error". Signals are properly routed and controlled to allow seamless operation. Tested with 8 and 32 MHz. IP operation. Dynamic Engineering uses IP-Debug-Bus in design/integration and production test.

Power is controlled with an on-board switch to allow the IP Module to be powered down without turning off the host system - hot swap operation. The logic signals are automatically isolated with "quick switch" technology when the power is disabled. LEDs indicate when power is applied. A remote connector position is supplied to allow a remote switch to control the power switching for production environments. "Self healing" fuses are provided for power protection.

Allow the host to connect the driver to the installed IP module. After that you can power the IP Module down to add test points, swap units etc. and power on to immediately use the same software "connection" to the IndustryPack device. Since the address is static no reload issues like you have with PCI, PCIe etc.

Narrow profile to allow use in pairs for double wide IP Modules, or just two modules in adjacent positions.

.002 ohm resistors in-line with power connections allow measurement of the IP power Epads provided on both sides of each measurement resistor to allow ease of measurement. Alternatively the resistor or inline fuse can be removed and an inline measurement device used.

Use with IP-Debug-IO for a complete debugging solution. IP-Debug-IO provides testpoints and a ribbon cable connector for the IO connector. The IP can be connected to the system through the ribbon cable connector and probed at the same time.

All IP Module control bus signals covered including rarely used ones like "error". Signals are properly routed and controlled to allow seamless operation. Tested with 8 and 32 MHz. IP operation. Dynamic Engineering uses IP-Debug-Bus in design/integration and production test.

Power is controlled with an on-board switch to allow the IP Module to be powered down without turning off the host system - hot swap operation. The logic signals are automatically isolated with "quick switch" technology when the power is disabled. LEDs indicate when power is applied. A remote connector position is supplied to allow a remote switch to control the power switching for production environments. "Self healing" fuses are provided for power protection.

Allow the host to connect the driver to the installed IP module. After that you can power the IP Module down to add test points, swap units etc. and power on to immediately use the same software "connection" to the IndustryPack device. Since the address is static no reload issues like you have with PCI, PCIe etc.

Narrow profile to allow use in pairs for double wide IP Modules, or just two modules in adjacent positions.

.002 ohm resistors in-line with power connections allow measurement of the IP power Epads provided on both sides of each measurement resistor to allow ease of measurement. Alternatively the resistor or inline fuse can be removed and an inline measurement device used.

Use with IP-Debug-IO for a complete debugging solution. IP-Debug-IO provides testpoints and a ribbon cable connector for the IO connector. The IP can be connected to the system through the ribbon cable connector and probed at the same time.

IP-Debug-Bus Features

Size

1.8" x 3.9"

Power

Passes 5V, 12V, -12V from carrier to attached IP Module. Switch provided to isolate power and signals from carrier/adapter - hot swap provided.

Mounting

Right angle connector to IndustryPack carrier/adapter and standard vertical connector to IP Module. Connectors oriented to provide component side of the IP Module on the top side for the assembly.

Test Points

Logic Analyzer etc. connections to the IP Control Bus are provided. Each is marked with silk-screen. .025 in sq. posts are compatible with most logic analyzers and ocilloscopes.

Reset

Push Button switch provided to allow the user to reset the IP without using the power switch or affecting attached computer.

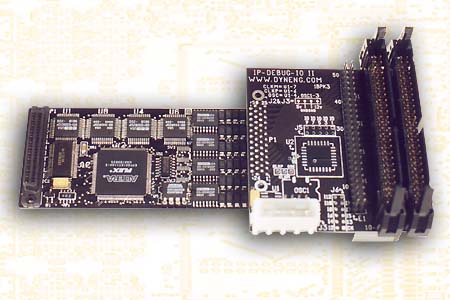

IP Debug IO in use. Left side of IP Module connects to IP-Debug-Bus

IP-Debug-Bus Benefits

Ease of Use

Plug together with system connections intact using IP-Debug-Bus and IP-Debug-IO. IP-Debug-Bus attaches to Carrier device - PCIe3IP for example - with IP under test attached to the other side of IP-Debug-Bus. IP-Debug-IO can be attached to the IO connector to provide system connections or simulated system connections [loop-back etc.]

Price

IP-Debug-Bus is available at a reasonable price and lead time. We keep in stock as this is frequently a "panic" purchase item. See the on-line storefront at the top of this page.

Compatibility

IP compatible allowing use with any standard carrier and IP Module. In some cases a modified chassis or riser for the carrier may be needed.

IP Debug Bus in use:. Left side of IP-Debug-Bus connects [plugs into] to Carrier / Adapter

Part Number:IP-Debug-Bus

Ordering Options

-

Standard board with testpoints on IP Module control, data, and reserved signals, LED indicators for Power, Hot Swap capability, reset switch, fuse protection.

-ROHS add for ROHS version.

Custom Length SCSI Cable

Send us an e-mail - sales@dyneng.com with your requirements. Be sure to include the length, retention [clip / screw], and quantity. Please be aware that custom lengths will take several weeks to process. Pricing is quantity sensitive.

HDRribn50 Additional Information

Reference Statement of Volatility