PMC-Parallel-TTL

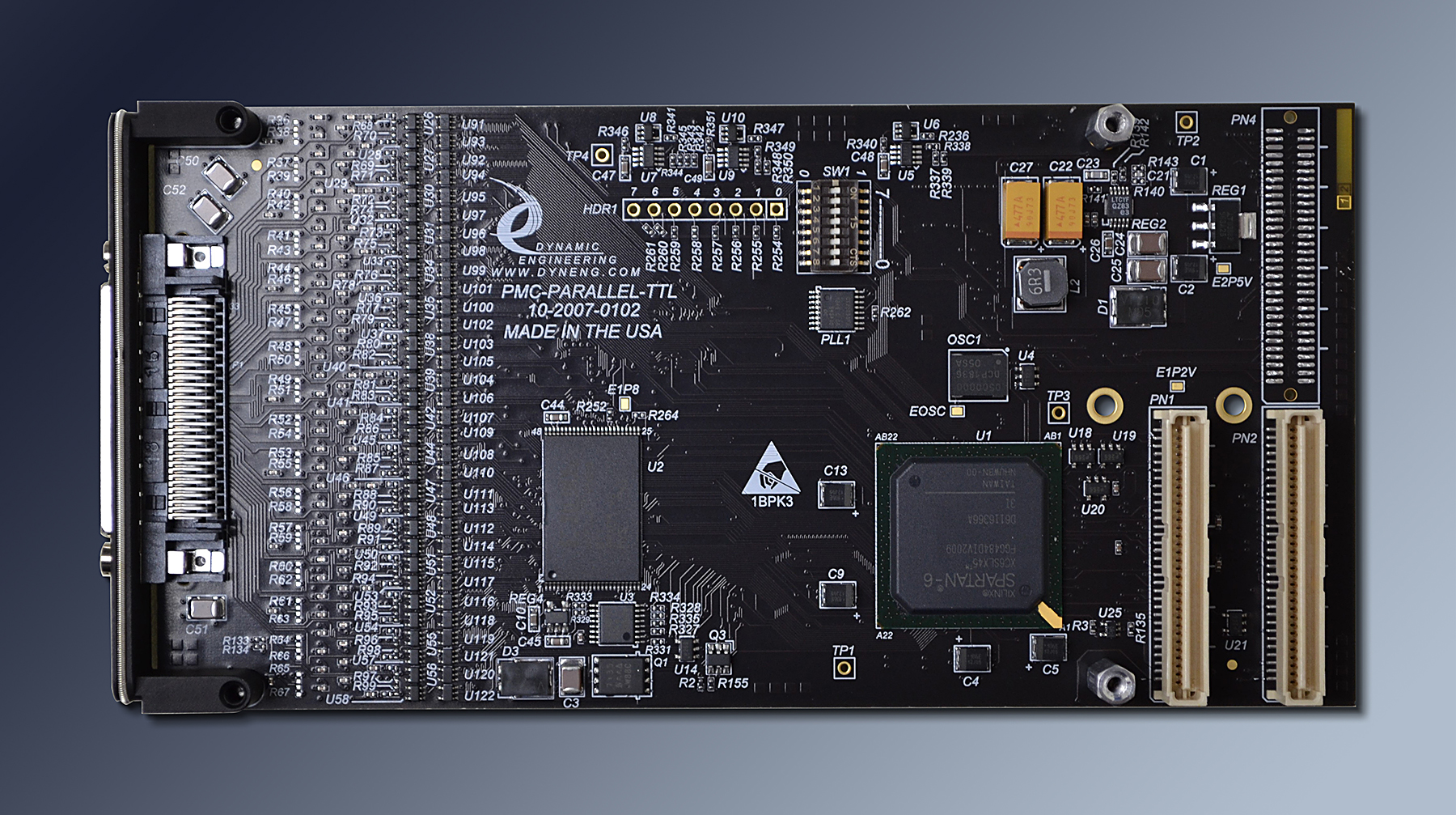

PMC Module with Spartan FPGA, PLL, 64 Independent IO

Order This Item

PMC-Parallel-TTL Description

- Driver included with purchase

- Standard PMC module

- 32/33 with DMA operation

- 64 independent IO. Each with programmable direction and COS interrupt.

- SW programmable IO levels [5V or 3.3V]

- Bezel and/or rear IO

- Spartan 6 FPGA with BRAM for FIFO or RAM implementation

- PLL with 4 clock references

- Temperature sensor

- 1 year warranty standard. Extended warranty available.

- ROHS and Standard processing available

Does your system require single ended TTL or CMOS level signals? Dynamic Engineering has a multitude of solutions covering different architectures and mezzanine types. With most architectures you have a choice with carriers for cPCI, PCI, PCIe, VPX, VME, PCI-104, and other buses for PMC, XMC and IP mezzanine modules. Usually your choice is based on other system constraints as the PMC, XMC, and IP can provide the IO you require. Dynamic Engineering can assist in your decision making regarding architecture and other trade-offs. Dynamic Engineering has carriers for IP, XMC, and PMC modules for most architectures, and is adding more as new solutions are requested by our customers.

The PMC compatible PMC-Parallel-TTL has 64 independent digital IO. The high density makes efficient use of precious PMC slot resources. The IO is available for system connection both through the front panel and via the rear [Pn4] connector. A high density 68 pin VHDCI front panel connector [rev 02 and later] provides the front panel IO. The rear panel IO has a PIM and PIM Carrier available for rear panel wiring options. The HDEterm68 can be used as a breakout for the front or rear panel IO.

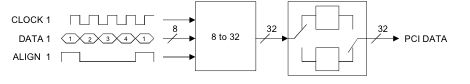

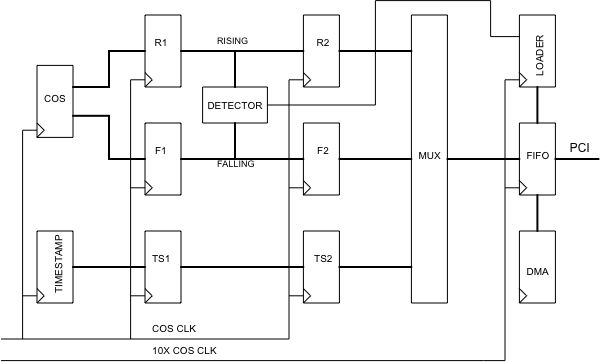

PMC-Parallel-TTL Block Diagram

PMC-Parallel-TTL base version block diagram

PMC Modules require a "carrier" in most cases to adapt them to the system. Dynamic Engineering has carrier solutions for a variety of formats.

PCIe implementations can be done with the PCIeBPMCX1 and PCIeBPMCX2.

PCI implementations can be done with the PCI2PMC and PCIBPMCX2.

cPCI 3U is supported with the cPCIBPMC3U64

cPCI 6U is supported with the cPCIBPMC6U.

PCI-104 is supported with the PCI104p2PMC.

Each IO is independently programmable. The outputs can be enabled and driven high or low. When disabled on-board pull-ups terminate the lines. The pull-ups can be referenced to 5V or 3.3V as an ordering option. A master enable is available to allow the user to synchronize the upper and lower outputs for coherant 64 bit operation in a 32 bit system. The master enable can be set to allow independent upper and lower bank updates.

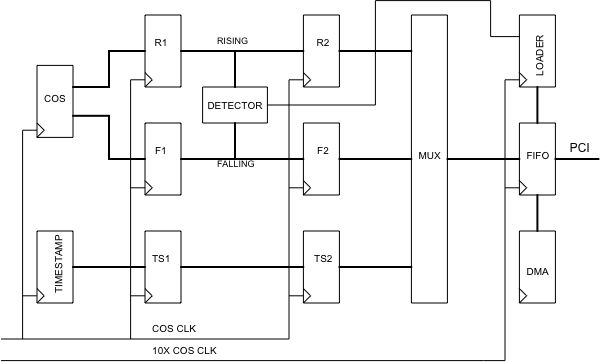

All channels can be read as inputs regardless of the transmit enable programming. Local loop-back can be used for BIT. All IO channels can be used as interrupt generators. Interrupts are programmable to be based on either or both edges for "Change of State" operation. An external clock, PCI clock, or oscillator can be selected for the reference on the COS operation. The reference can be programmed to be divided to create lower frequencies. A PLL is available to support user frequency selection to provide the right sampling rate for your application.

All of the IO are routed through the FPGA device to allow for custom applications that require hardware intervention or specific timing. For example the design of the PMC-Parallel-TTL supports internal FIFO´s and DMA. With an added state-machine for your interface the hardware can provide much more than a simple parallel interface. The 64 IO can be configured to support one function, one function replicated several times, or multiple functions. A real space saver when you need to have some Manchester to go with your UART and HDLC ports. A partial list of functions includes: Manchester, Miller, SDLC, UART, Serial, Parallel, GPIO, COS, Custom, LADEE, NMS, Camera, Ternary, Low Speed, High Speed, Telemetry, Master & Target interactive IO, Adaptive. To support the functions the designs include: memory elements instantiated with FIFO, Dual Port RAM, register files, as well as state-machines, counters, timers, dividers, registers, CRC and Parity generation / checking, software drivers and applications, DMA [direct memory access] and the glue that goes with it. Our designs are all written in VHDL and done in a heirarchy allowing direct porting of different features to create new implementations. Contact Dynamic Engineering for client specific implementations.

What do you need to communicate with? Control? Capture data from? Please see the Models Tab for implementation descriptions and manuals for customerized versions. We have been doing custom design work since 1988

A new custom version can be implemented in a very reasonable time. Typically 2-3 weeks of design time for a medium sized project including the new VHDL set, Windows® or Linux or VxWorks driver, reference software package, and documentation. Examples of the designs performed to date are listed toward the bottom of this page and pages for previous versions. Check if the configuration you need already exists or if we need to work on a custom version for you.

We can be rapid with our response because the designs are structured to allow ports to be moved in and out to create new design sets. Most designs have a fairly large component of reused "known good" VHDL that we can pull from allowing us to focus on the new functions required for your implementation. You are getting the benefit of many man-years of design and test time with each new version created. Join our high reliability clients by taking advantage of our know-how to help speed your project to completion. email us your wish list or call today

The base model has a simple to use register based interface. The registers are mapped as 32 bit words. All registers are read-writeable. The Windows® compatible driver is available to provide the system level interface for this design. Use standard C/C++ to control your hardware or use the Hardware manual to make your own software interface. The hardware and software manuals are downloadable from the Models Tab

PMC-Parallel-TTL can be used along with a PCIe or other carrier/adapter to use with a variety of system types - PCI, PCIe, PC104p, VPX cPCI, etc.. Dynamic Engineering has PMC carriers for PCI, PCIexpress, cPCI, PC104p, and can do custom design´s specific to client requirements as well. Please use the handy pull-down menu at the top of any page to navigate to other Dynamic Engineering products including carriers.

PMC´s are independently specificed through VITA for the form factor, connectors and pinouts of the PCI signaling; you can use with any carrier from any vendor that supports standard PMC´s. To make it even easier Dynamic Engineering PMC´s feature a universal voltage PCI design to allow operation with VIO set to 3.3 or 5V.

It all starts with the PCB [Printed Circuit Board]. Quality design and quality materials are required to meet the strenuous requirements of many of our implementations. You can do the job quickly or you can do the design correctly. We pride ourselves on taking the time to put the extra work into our layouts. The quality goes in before the parts go on. In addition to routing strategy and layer counts, Via size, plating requirements, break-out trace widths, and materials are areas where quality comes into play. The via size and method of trace attachment to the via affect the signal shape and reliability. Using tear-drop trace connections to pads, via´s and through hole components enhance the reliability and minimize the impedance discontinuity resulting in a cleaner signal. Using 10/12 mil vias provides adequate copper for proper power distribution and more surface area to bond to where traces are interconnected. The combination provides better vibration endurance than smaller vias and traces would provide. The design has several power planes with sufficient copper weight and coverage to provide the references required for the routing plus the current and voltages needed by the various devices on the board. The larger features make the design work more difficult since there is less room to "play with" and the end result is worth it. Since 1998 Dynamic Engineering designs have enjoyed an excellent track record for reliability.

The PCI interface has a published set of requirements for compliance which restrict length, impedance, loading and other factors. PMC-Parallel-TTL is compliant with the PCI Specification. The IO section has requirements based on the IO type and the purpose for the IO. A very conservative approach has been taken to allow operation with any client requirement. The design has matched length connections from the FPGA ball to the seating plane of the connector. The lengths are matched to the "mil". The Impedance is controlled and the signals routed with proper spacing to avoid cross talk etc. The other features including memory, PLL, oscillator, and power supplies are implemented within the PCB to exceed the operational requirements for those devices.

The IO is available through either the front panel mounted SCSI III connector or Pn4 or some combination. Each IO is isolated from the connectors with zero ohm resistors. The resistors are mounted front and rear and tied together at each IO to allow for a stub length of 1/16th in. The Connectors are routed from the resistors directly allowing for almost zero stub lengths and the option to connect front or rear IO options.

Clock options are frequently a major factor in embedded designs. Getting the right reference to the right part of the design and allowing for local control of exact frequencies. With a PLL providing 4 programmable outputs, reference oscillator, internal DCM´s and buffering plus programable dividers instantiated within the VHDL. The PLL can be programmed to "any" fixed frequency, the DCM used to create phase variations, and local dividers to allow on-the-fly channel based frequency changes.

"Channelized DMA"™ is an important feature of the PMC- Parallel - TTL design. With "Channelized DMA"™ you have a separate DMA engine for each transmitter and each receiver within each port. Each state-machine can be serviced independently with DMA without requiring intervention from the host. Large data transfers can happen between multiple connections while the CPU is off doing something else. In non-channelized designs the CPU will have to intervene each time a different port needs to be serviced. With a channelized approach the hardware takes care of the local arbitration, and eliminates the intervention for better system performance and less latency.

The PMC compatible PMC-Parallel-TTL has 64 independent digital IO. The high density makes efficient use of precious PMC slot resources. The IO is available for system connection both through the front panel and via the rear [Pn4] connector. A high density 68 pin VHDCI front panel connector [rev 02 and later] provides the front panel IO. The rear panel IO has a PIM and PIM Carrier available for rear panel wiring options. The HDEterm68 can be used as a breakout for the front or rear panel IO.

PMC-Parallel-TTL base version block diagram

PCIe implementations can be done with the PCIeBPMCX1 and PCIeBPMCX2.

PCI implementations can be done with the PCI2PMC and PCIBPMCX2.

cPCI 3U is supported with the cPCIBPMC3U64

cPCI 6U is supported with the cPCIBPMC6U.

PCI-104 is supported with the PCI104p2PMC.

Each IO is independently programmable. The outputs can be enabled and driven high or low. When disabled on-board pull-ups terminate the lines. The pull-ups can be referenced to 5V or 3.3V as an ordering option. A master enable is available to allow the user to synchronize the upper and lower outputs for coherant 64 bit operation in a 32 bit system. The master enable can be set to allow independent upper and lower bank updates.

All channels can be read as inputs regardless of the transmit enable programming. Local loop-back can be used for BIT. All IO channels can be used as interrupt generators. Interrupts are programmable to be based on either or both edges for "Change of State" operation. An external clock, PCI clock, or oscillator can be selected for the reference on the COS operation. The reference can be programmed to be divided to create lower frequencies. A PLL is available to support user frequency selection to provide the right sampling rate for your application.

All of the IO are routed through the FPGA device to allow for custom applications that require hardware intervention or specific timing. For example the design of the PMC-Parallel-TTL supports internal FIFO´s and DMA. With an added state-machine for your interface the hardware can provide much more than a simple parallel interface. The 64 IO can be configured to support one function, one function replicated several times, or multiple functions. A real space saver when you need to have some Manchester to go with your UART and HDLC ports. A partial list of functions includes: Manchester, Miller, SDLC, UART, Serial, Parallel, GPIO, COS, Custom, LADEE, NMS, Camera, Ternary, Low Speed, High Speed, Telemetry, Master & Target interactive IO, Adaptive. To support the functions the designs include: memory elements instantiated with FIFO, Dual Port RAM, register files, as well as state-machines, counters, timers, dividers, registers, CRC and Parity generation / checking, software drivers and applications, DMA [direct memory access] and the glue that goes with it. Our designs are all written in VHDL and done in a heirarchy allowing direct porting of different features to create new implementations. Contact Dynamic Engineering for client specific implementations.

What do you need to communicate with? Control? Capture data from? Please see the Models Tab for implementation descriptions and manuals for customerized versions. We have been doing custom design work since 1988

A new custom version can be implemented in a very reasonable time. Typically 2-3 weeks of design time for a medium sized project including the new VHDL set, Windows® or Linux or VxWorks driver, reference software package, and documentation. Examples of the designs performed to date are listed toward the bottom of this page and pages for previous versions. Check if the configuration you need already exists or if we need to work on a custom version for you.

We can be rapid with our response because the designs are structured to allow ports to be moved in and out to create new design sets. Most designs have a fairly large component of reused "known good" VHDL that we can pull from allowing us to focus on the new functions required for your implementation. You are getting the benefit of many man-years of design and test time with each new version created. Join our high reliability clients by taking advantage of our know-how to help speed your project to completion. email us your wish list or call today

The base model has a simple to use register based interface. The registers are mapped as 32 bit words. All registers are read-writeable. The Windows® compatible driver is available to provide the system level interface for this design. Use standard C/C++ to control your hardware or use the Hardware manual to make your own software interface. The hardware and software manuals are downloadable from the Models Tab

PMC-Parallel-TTL can be used along with a PCIe or other carrier/adapter to use with a variety of system types - PCI, PCIe, PC104p, VPX cPCI, etc.. Dynamic Engineering has PMC carriers for PCI, PCIexpress, cPCI, PC104p, and can do custom design´s specific to client requirements as well. Please use the handy pull-down menu at the top of any page to navigate to other Dynamic Engineering products including carriers.

PMC´s are independently specificed through VITA for the form factor, connectors and pinouts of the PCI signaling; you can use with any carrier from any vendor that supports standard PMC´s. To make it even easier Dynamic Engineering PMC´s feature a universal voltage PCI design to allow operation with VIO set to 3.3 or 5V.

It all starts with the PCB [Printed Circuit Board]. Quality design and quality materials are required to meet the strenuous requirements of many of our implementations. You can do the job quickly or you can do the design correctly. We pride ourselves on taking the time to put the extra work into our layouts. The quality goes in before the parts go on. In addition to routing strategy and layer counts, Via size, plating requirements, break-out trace widths, and materials are areas where quality comes into play. The via size and method of trace attachment to the via affect the signal shape and reliability. Using tear-drop trace connections to pads, via´s and through hole components enhance the reliability and minimize the impedance discontinuity resulting in a cleaner signal. Using 10/12 mil vias provides adequate copper for proper power distribution and more surface area to bond to where traces are interconnected. The combination provides better vibration endurance than smaller vias and traces would provide. The design has several power planes with sufficient copper weight and coverage to provide the references required for the routing plus the current and voltages needed by the various devices on the board. The larger features make the design work more difficult since there is less room to "play with" and the end result is worth it. Since 1998 Dynamic Engineering designs have enjoyed an excellent track record for reliability.

The PCI interface has a published set of requirements for compliance which restrict length, impedance, loading and other factors. PMC-Parallel-TTL is compliant with the PCI Specification. The IO section has requirements based on the IO type and the purpose for the IO. A very conservative approach has been taken to allow operation with any client requirement. The design has matched length connections from the FPGA ball to the seating plane of the connector. The lengths are matched to the "mil". The Impedance is controlled and the signals routed with proper spacing to avoid cross talk etc. The other features including memory, PLL, oscillator, and power supplies are implemented within the PCB to exceed the operational requirements for those devices.

The IO is available through either the front panel mounted SCSI III connector or Pn4 or some combination. Each IO is isolated from the connectors with zero ohm resistors. The resistors are mounted front and rear and tied together at each IO to allow for a stub length of 1/16th in. The Connectors are routed from the resistors directly allowing for almost zero stub lengths and the option to connect front or rear IO options.

Clock options are frequently a major factor in embedded designs. Getting the right reference to the right part of the design and allowing for local control of exact frequencies. With a PLL providing 4 programmable outputs, reference oscillator, internal DCM´s and buffering plus programable dividers instantiated within the VHDL. The PLL can be programmed to "any" fixed frequency, the DCM used to create phase variations, and local dividers to allow on-the-fly channel based frequency changes.

"Channelized DMA"™ is an important feature of the PMC- Parallel - TTL design. With "Channelized DMA"™ you have a separate DMA engine for each transmitter and each receiver within each port. Each state-machine can be serviced independently with DMA without requiring intervention from the host. Large data transfers can happen between multiple connections while the CPU is off doing something else. In non-channelized designs the CPU will have to intervene each time a different port needs to be serviced. With a channelized approach the hardware takes care of the local arbitration, and eliminates the intervention for better system performance and less latency.

PMC- Parallel - TTL Features

Size

Std PMC 74mm x 149mm nominal. Low profile components on rear

IO

64 independent IO. The pull-ups can be referenced to 3.3V or 5V. Front Panel [Bezel], Rear IO [Pn4] or Both ports available. Unused ports isolated with resistors for "zero bus stub". Matched IO within 1/1000 inch for on-board traces to front and rear.

Clocks

33 MHz PCI, 50 MHz oscillator ( other frequencies available), 4 programmable PLL inputs, Counters / Dividers / DCM for local clock control.

Interface Types

Custom programmed interfaces are available. Please send us a timing diagram, and we can program one for you. Most interfaces can be adapted from our large library of designs within 2-3 weeks including the updated VHDL, Windows or Linux or VxWorks Driver, reference manuals etc. We can support on-site [ours] integration to help you get your application level software working.

Alternatively choose one of the already completed versions and purchase off-the-shelf. Common requested and implemented interface types include: Manchester, Miller, SDLC, UART, Serial, Parallel, GPIO, COS, Custom, LADEE, NMS, Camera, Ternary, Low Speed, High Speed, Telemetry, Master & Target interactive IO, Adaptive. Mix and Match. Just like but different...

Alternatively choose one of the already completed versions and purchase off-the-shelf. Common requested and implemented interface types include: Manchester, Miller, SDLC, UART, Serial, Parallel, GPIO, COS, Custom, LADEE, NMS, Camera, Ternary, Low Speed, High Speed, Telemetry, Master & Target interactive IO, Adaptive. Mix and Match. Just like but different...

Pull-up Resistor

470 standard, 1K, 4.7K available. Double pull-ups available

Software Interface

Control registers are read-writeable

Windows®, Linux, VxWorks reference SW and Drivers

Windows®, Linux, VxWorks reference SW and Drivers

Interrupts

Software programmable interrupts on status, errors, completion of transfer, DMA, FIFO levels, custom events. Status can be polled for non-interrupt driven operation as well. All IO Channels can be programmed to cause interrupts. Each IO is programmable to be masked, rising, falling, both [COS]. Interrupts are mapped to INTA on PCI bus.

Power Requirement

+5V converted to 3.3V, 2.5, 1.2 with local DC:DC power supplies for efficient power conversion.

Protection

The isolation resistor standard is 0 ohms to Pn4 and 22 ohms to Bezel. Resistive coupling for current limiting and ESD protection

COS Clock

Input registers are programmable to capture data with the COS clk. SW can select PCI, external or Oscillator as the source for clock. A programmable divider allows a wide range of sampling frequencies to be selected. Some versions use the PLL for the COS clock definition.

Reliability

TBD million hours. Bellcore. GB 25c

Statement of Volatility

PMC- Parallel - TTL Benefits

Speed

PMC-Parallel-TTL is a software controlled HW interface. As fast as the PCI interface can push the data across, the outputs can change. With the Windows® driver several accesses per microsecond can be achieved. Your time to market will be shortened by the easy to use interface, flexibility in design, and off-the-shelf availability. With DMA enabled and FIFO´s instantiated even faster transfers can occur.

Price

PMC-Parallel-TTL has an attractive price, and low integration cost for a low system cost. PMC-Parallel-TTL has an associated PIM and PIM Carrier which can lead to further savings in cPCI environments.

Ease of Use

PMC- Parallel - TTL is designed to be easy to use. Direct access to all features, aligned registers for larger access types, programmable features to allow personalization for your system. Please download the manuals and see for yourself. Reference software is provided in source form to get you started.

Availability

PMC-Parallel-TTL is a stocked design. A quick "PCO" to reflash and retest into your configuration when ordering an existing version. New NRE required designs will have some delay to implement, integrate and test.

PMC Specification Compatibility

PMC-Parallel-TTL is compliant per the VITA PMC/CMC specifications. Tested with PCI and PCIe based carriers. All Dynamic Engineering PMC Modules are compatible with the PCIeBPMCX1, PMC-Parallel-TTL will operate with any PMC specification compliant carrier board.

Part Number: PMC-Parallel-TTL

Ordering Options

- PMC-Parallel-TTL Standard board - with programmable 5/3.3V IO. Temperature Sensor, Dipswitch, Front Panel [Bezel] IO

- -RP Switch to Pn4 IO

- -FRP Switch to Front and Rear IO

- -ROHS Use ROHS processing. Standard processing is ""leaded"

- -CC Option to add Conformal Coating

- -TS Add thumbscrew adapters

PMC-Parallel-TTL Drivers

Software Support for PMC-Parallel-TTL-XXX includes: Windows, and Linux compliant drivers. VxWorks by special request.

Please see the Driver manuals for the specifics of each type.

Drivers and Reference SW are developed for each type / version of PMC-Parallel-TTL implemented. When custom versions are ordered the NRE will include providing Windows, Linux, and or VxWorks packages. For off-the-shelf models, select on the models tab, the Windows® and Linux SW shown is included with your purchase of the HW. A one-time charge is required for the VxWorks versions. Unsupported SW versions may have an NRE requirement.

Integration support is available. Please contact Dynamic Engineering for this option or download the Technical Support Description from the Company button.

Please see the Driver manuals for the specifics of each type.

Drivers and Reference SW are developed for each type / version of PMC-Parallel-TTL implemented. When custom versions are ordered the NRE will include providing Windows, Linux, and or VxWorks packages. For off-the-shelf models, select on the models tab, the Windows® and Linux SW shown is included with your purchase of the HW. A one-time charge is required for the VxWorks versions. Unsupported SW versions may have an NRE requirement.

Integration support is available. Please contact Dynamic Engineering for this option or download the Technical Support Description from the Company button.

PMC-Parallel-TTL Models

GPIO 64 TTL IO in a General Purpose IO configuration

Change of State [COS] with independent Rising and Falling selections to allow for data capture on either, neither, or both edges. Edge or Level selection to allow treating IO as level based. Separate interrupt enables for each IO. Independent polarity selection. Multiple programmable COS rates based on programmable PLL and local oscillator [16 bit divisor]. Dip Switch for user purposes. Temperature sensor. VHDCI and/or Rear connector options. Synchronization for upper and lower words can be used to control all 64 bits together or disabled for 2 32 bit ports. All bits can be read-back. Programmable Tx bits. Programmable IO reference [5V or 3.3V]. Design supports internal loop-back. Unified driver supports PMC and XMC models.

DMA support with 8Kx32 FIFO for user purposes.

Driver has utilities for programming the PLL using the "JED" file, reading the temperature, and managing all of the features.

Download the Parallel-TTL-GPIO Win10 Driver Package Manual

Download the Parallel-TTL-GPIO Linux Driver Package Manual

Download the Parallel-TTL-GPIO HW Manual

BA16 has the standard features of the PMC-Parallel-TTL plus:

Two synchronous parallel ports - 8 bits with reference clock and strobe.

DMA support with 4Kx32 FIFO on RX, and 2Kx32 FIFO on TX.

Driver has utilities for programming the PLL using the "JED" file.

Download the PMC-Parallel-TTL-BA16 Hardware Manual in PDF format.

Download the PMC-Parallel-TTL-BA16 Windows® XP Manual for BA16 version in PDF format.

Download the PMC-Parallel-TTL-BA16 Windows® 7 Manual for BA16 version in PDF format.

*The Linux manual is embedded in Linux source files for this project.

BA17 has the standard features of the PMC-Parallel-TTL plus:

DMA support for the COS function on the upper 32 bits with 12K x 32 FIFO.

Programmable [PLL] COS sample rate.

Driver has utilities for programming the PLL using the "JED" file.

Download the PMC-Parallel-TTL-BA17 Hardware Manual in PDF format.

Download the PMC-Parallel-TTL-BA17 Windows® Manual for BA17 version in PDF format.

BA21 implements 4 i2c interfaces and a 32 bit parallel port:

DMA support for the four channels of i2c. 1Kx32 FIFO for Write, and 1Kx32 FIFO for Read, plus a Packet Length FIFO in each channel.

Programmable [PLL] I2C rate to support Standard and Fast operational modes.

Write, Read, Snoop functions. Programmable Target address. 32 bit parallel port.

Driver has utilities for programming the PLL using the "JED" file.

Can be ported to XMC version of the card.

Download the PMC-Parallel-TTL-BA21 Hardware Manual in PDF format.

Change of State [COS] with independent Rising and Falling selections to allow for data capture on either, neither, or both edges. Edge or Level selection to allow treating IO as level based. Separate interrupt enables for each IO. Independent polarity selection. Multiple programmable COS rates based on programmable PLL and local oscillator [16 bit divisor]. Dip Switch for user purposes. Temperature sensor. VHDCI and/or Rear connector options. Synchronization for upper and lower words can be used to control all 64 bits together or disabled for 2 32 bit ports. All bits can be read-back. Programmable Tx bits. Programmable IO reference [5V or 3.3V]. Design supports internal loop-back. Unified driver supports PMC and XMC models.

DMA support with 8Kx32 FIFO for user purposes.

Driver has utilities for programming the PLL using the "JED" file, reading the temperature, and managing all of the features.

Download the Parallel-TTL-GPIO Win10 Driver Package Manual

Download the Parallel-TTL-GPIO Linux Driver Package Manual

Download the Parallel-TTL-GPIO HW Manual

BA16 has the standard features of the PMC-Parallel-TTL plus:

Two synchronous parallel ports - 8 bits with reference clock and strobe.

DMA support with 4Kx32 FIFO on RX, and 2Kx32 FIFO on TX.

Driver has utilities for programming the PLL using the "JED" file.

Download the PMC-Parallel-TTL-BA16 Hardware Manual in PDF format.

Download the PMC-Parallel-TTL-BA16 Windows® XP Manual for BA16 version in PDF format.

Download the PMC-Parallel-TTL-BA16 Windows® 7 Manual for BA16 version in PDF format.

*The Linux manual is embedded in Linux source files for this project.

BA17 has the standard features of the PMC-Parallel-TTL plus:

DMA support for the COS function on the upper 32 bits with 12K x 32 FIFO.

Programmable [PLL] COS sample rate.

Driver has utilities for programming the PLL using the "JED" file.

Download the PMC-Parallel-TTL-BA17 Hardware Manual in PDF format.

Download the PMC-Parallel-TTL-BA17 Windows® Manual for BA17 version in PDF format.

BA21 implements 4 i2c interfaces and a 32 bit parallel port:

DMA support for the four channels of i2c. 1Kx32 FIFO for Write, and 1Kx32 FIFO for Read, plus a Packet Length FIFO in each channel.

Programmable [PLL] I2C rate to support Standard and Fast operational modes.

Write, Read, Snoop functions. Programmable Target address. 32 bit parallel port.

Driver has utilities for programming the PLL using the "JED" file.

Can be ported to XMC version of the card.

Download the PMC-Parallel-TTL-BA21 Hardware Manual in PDF format.